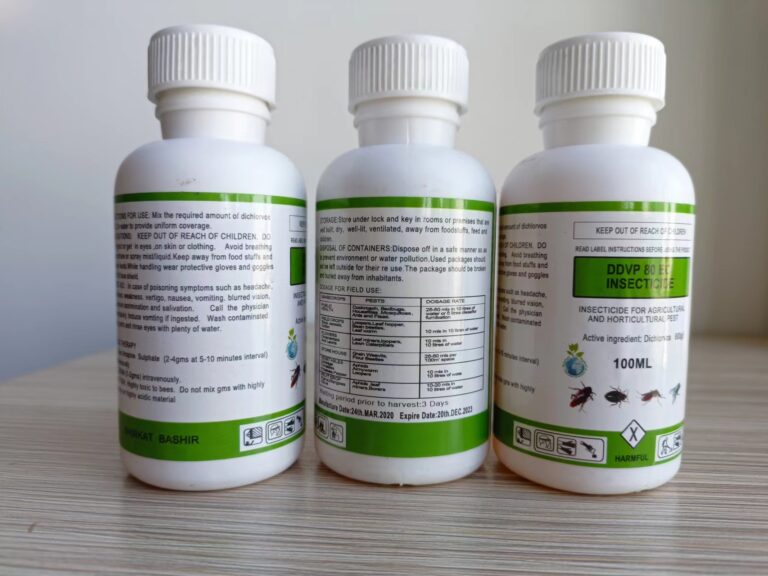

Introducing Pesticide Bottles

When choosing a pesticide bottle, the choice of material plays a vital role. The complexity of plastic consumption channels and the difficulty of distinguishing post-consumer plastics. These make it crucial to clearly mark the type of material on plastic products. Here, we share insights into the materials used in pesticide bottles, focusing on practical tips that can work to your benefit.

Pesticide bottle material types

Pesticide bottles are typically made from three main materials. Polyethylene terephthalate (PET), barrier bottles, and polyvinyl chloride (PVC).

- Polyethylene terephthalate (PET)

PET is the material of choice for common pesticide bottles.

Can be used directly in pharmaceutical packaging without extensive cleaning or drying.

Lightweight, high-strength, damage-resistant, good sealing, and moisture-proof.

- Isolation bottle

For corrosive pesticides, choose high-barrier bottles that add film inside the PET for added resistance.

- Polyvinyl chloride (PVC)

PVC is chemically stable but should not come into contact with food.

Appearance similar to polycarbonate. It is difficult to burn, the flame is yellow, the edges are green, softened, and there is an obvious burnt smell.

Other materials on the market

In addition to the above materials, there are several other materials commonly available on the market, including PET, PEPA, HDPE, F-HDPE, and PE. Aluminum foil is also an option, available in three, four or five layers.

Things to note about aluminum foil

A variety of aluminum foil materials exist, with three, four or five layers.